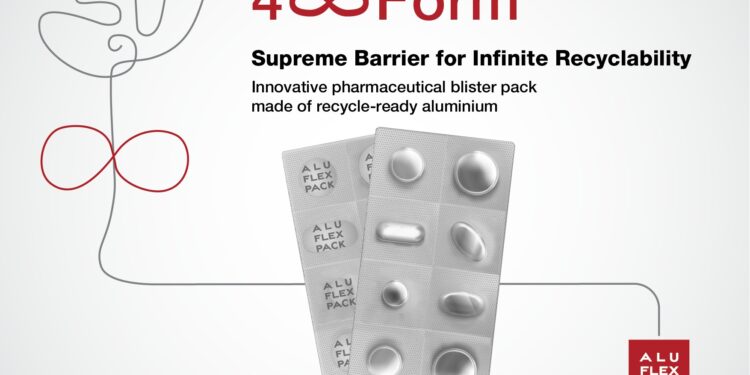

The 4∞ Form is a pharmaceutical blister pack made entirely from lacquered aluminum. This means it is ideal for recycling, has effective protective properties and complies with current and prospective pharmaceutical and packaging legislation, such as the recently adopted Packaging and Packaging Waste Regulation (PPWR).

4∞ Form is primarily designed for use in the pharmaceutical industry, where it can replace existing solutions such as OPA/AL/PVC (cold form) or PVC/PVDC (thermoform) used for packaging tablets, capsules and similar products. The highlight here is that the innovative Aluflexpack packaging is made entirely of lacquered aluminum. As the product name suggests, aluminum is a material that can be recycled indefinitely or indefinitely without losing any of the properties that are so important in the packaging industry with regard to product safety and the preservation of product quality.

Aluminum is extremely lightweight and can withstand both high and low temperatures. It offers 100% protection against bacteria and microorganisms, as well as moisture, light, oxygen and other gases. Products in flexible aluminum packaging therefore offer a much longer shelf life.

Johannes Steurer, CEO of Aluflexpack, is very pleased with the new product:

“As a flexible packaging company that has been developing aluminum-based products for more than 40 years, we stand behind all that aluminum has to offer, especially the protection factor. We are constantly in touch with our customers and exploring different ways we can use aluminum to help them on their packaging journey. New market-driving regulations have encouraged us to try something no one has done before: to form lacquered aluminum into a new, fully recyclable product for the pharmaceutical industry! By utilizing our strong network of suppliers and partners, but more importantly the experience and deep industrial knowledge of our R&D department, we were able to find a new solution that can shape the pharmaceutical market in a new and more sustainable direction.”

The product can be customized for all customers’ needs, including shape, printing and branding, and can be used for packaging different products such as antibiotics and over-the-counter medicines due to the strong protection it offers.

Aluflexpack is committed to sustainability, as evidenced by numerous certifications. In May 2024, Aluflexpack was awarded a gold medal by EcoVadis, which evaluates sustainability performance in four main aspects: environment, labor and human rights, sustainable procurement and ethics. Aluflexpack was thus ranked in the top 1% of companies in the printing industry assessed by EcoVadis. Aluflexpack also develops circular solutions that fully comply with the European Union Packaging and Packaging Waste Regulation (PPWR). In addition, the company remains committed to the Science-Based Targets initiative in its efforts to minimize negative impacts on the environment.